Functions & Designs of Plastic Pallets

Plastic Pallet Functions and Designs

Plastic pallets are built to support a wide variety of functions and environments.

Each function typically relies on a specific design style to safely and efficiently get the job done. Use the guide below to dive into an overview of styles and the duties they carry out.

This post is part 2 of a 10-post series on Plastic Pallets 101. (Part 1 introduces plastic pallet anatomy.)

The scope of plastic pallet design includes runner configurations, weights, molding styles and materials.

Find your Design

Matching your application with fitting design styles is just one step in selecting the right plastic pallet.

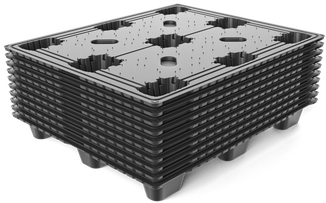

Nestable

- Have hollow feet (usually 9)

- Pallets fit snugly (or nest) one on top of the other

- Offers stack security when not in use

- Lightweight nestables save on space and freight

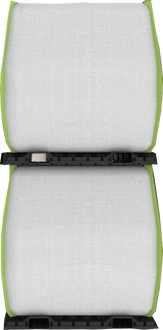

Stackable

- Designed to stack one load on top of the next

- Loads are often stacked 2-3 high

- Can be both a unit base and a divider for block stacking

- Both 3 and 6-runner bottom styles may be suitable

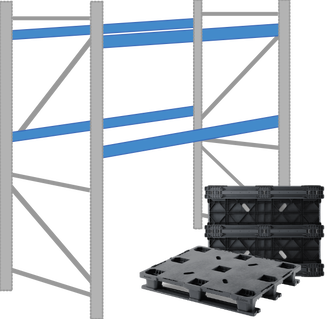

Rackable

- Think warehouses or Distribution Centers using racking systems

- Use with beam, edge, roller, push-back, flow, cantilever and supported pallet racks

- Stiff enough to bridge a span in an unsupported open rack

- Heavyweight to meet demanding load capacities

- Robust understructures in 3 and 6-runner designs

One-Piece

- Solid body construction with no seams or welds

- Reduces weak points

- Simpler design is easier to keep clean

- Popular with pharmaceutical and direct-contact uses

- Helps avoid pest and water intrusions

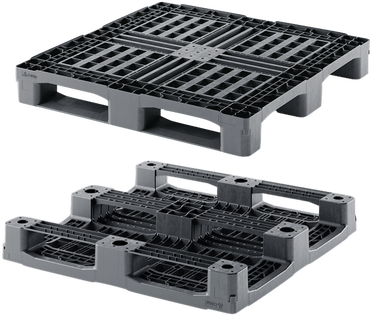

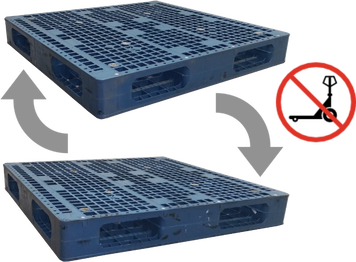

Reversible

- Also known as double-sided pallets

- Virtually identical tops and bottoms

- Always right side up (increase productivity)

- Not suitable for pallet jacks

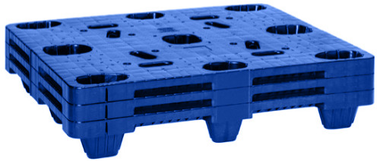

Full Perimeter

- Think picture frame

- Rails or supports on all 4 sides of the base

- May have a 5th support or 6 rails (shown)

- Popular design for repeated use in warehouses or closed loops

Speciality Handling

- Virgin materials meet stringent hygiene guidelines for direct food contact

- Pharmaceutical pallets are suitable for heat sterilization

- Fire retardant materials meet standards for fire safety

- Freezer additives help to make plastic more resilient in colder temps

Learn More about Plastic Pallets

Be sure to catch our quick Plastic Pallets 101 Video. In just 10 short minutes, we introduce you to even more basics about choosing plastic pallets. If you have questions, let's connect for expert plastic pallet advice.

1/27/2023 by Mike Cunneen on Plastic Pallets 101